The process of creating new architectural doors begins with collaboration and design. Whether we work with a design firm or directly with the owner, the entry is carefully engineered and defined through our drawing process.

Our custom built architectural doors can be made in a variety of premium grade hardwoods. The construction of our doors meet the highest standards of traditional joinery that withstand the test of time. We utilize stave core construction for the stiles and rails so that they remain flat and true. The traditional joinery of through mortise and tenon is the standard by which connect our stiles and rails.

All moldings and door panels are milled to design specifications and are meticulously incorporated within the door’s components. We use premium grade waterproof adhesives to glue all joinery. The finished assembly is then carefully hand detailed and sanded in preparation for finish.

The assembled door is now ready to be fit to its complementary components, the custom frame and sill. Once properly sized, hinge mortises are cut and the door is hung in the frame. The mortise lockset is then housed in its stile and the adjoining strike plate is mortised in the jamb. Proper functionality is carefully checked in preparation of the last hardware component, weatherstrip. Our standard weatherstrip system includes bronze interlock at the side and head jambs with a bronze interlock saddle at the wood sill.

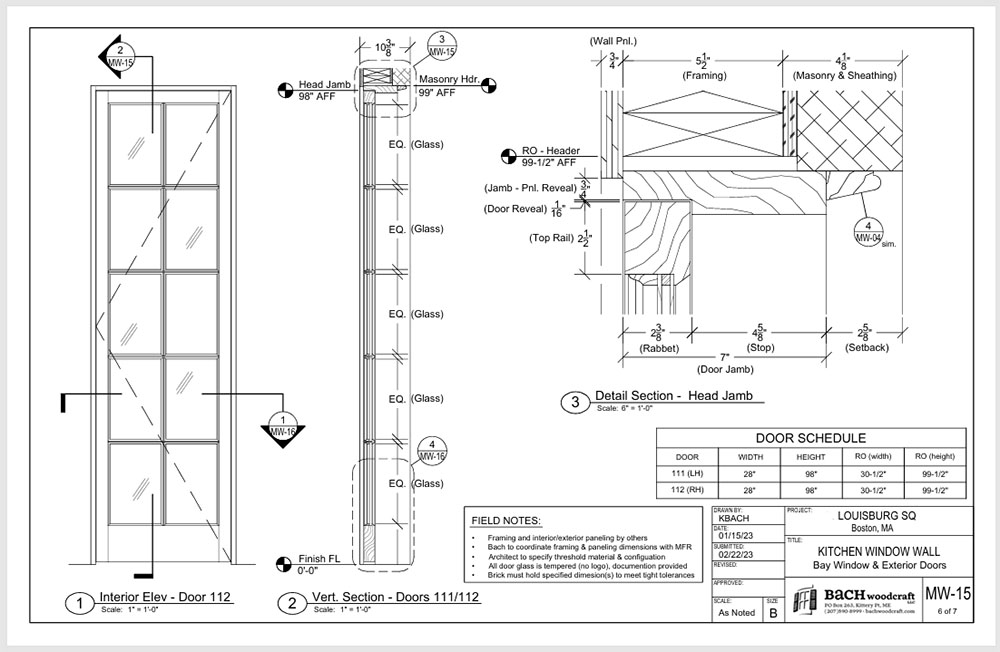

For architectural doors with glass panes, we incorporate tempered insulating glass as individual panes within each opening. We carefully size the glass for a clean sight line between the glass spacer and the wood muntin. Each pane is bedded in Sarco putty and secured with an interior wood stop that is profiled to the specified sticking design. We are able to provide a minimum muntin width of 15/16″. This process affords easy removal of the glass in the future with minimal impact on the integrity of the door.

For opaque finishes, (2) coats of tinted oil based primer are spray applied with sanding between coats. Exterior topcoats (3-4) are spray applied with oil based paint to the color and sheen specified. Our standard exterior finish utilizes Benjamin Moore Super Spec with a semi-gloss sheen. For high gloss finishes, an upgrade to Fine Paints of Europe HollandLac Brilliant is an option. Interior topcoats receive (3-4) spray coats of oil based Benjamin Moore satin Impervo to the color specified.

For natural finishes, the bare wood is sealed and stained to color specifications. Interior topcoats are spray applied with a catalyzed amino alkyd for an extremely durable finish. The exterior is finished with multiple topcoats of marine grade spar urethane that provides long lasting protection.

The last step to completion is delivery and installation. We will meticulously perform the installation or deliver it to your contractor to install. Our attention to detail throughout the process results in an elegant entryway that truly enhances your home’s architectural style.